Ínico do conteúdo da página

Overview

The application of metallic coatings by the continuous process of hot dipping is one of the most used forms for protection of steel. In this process, the metal strip is continuously immersed in a molten metal bath. Among the metal coatings suitable to the application of the heat immersion process, we can mention the Galvalume alloy.

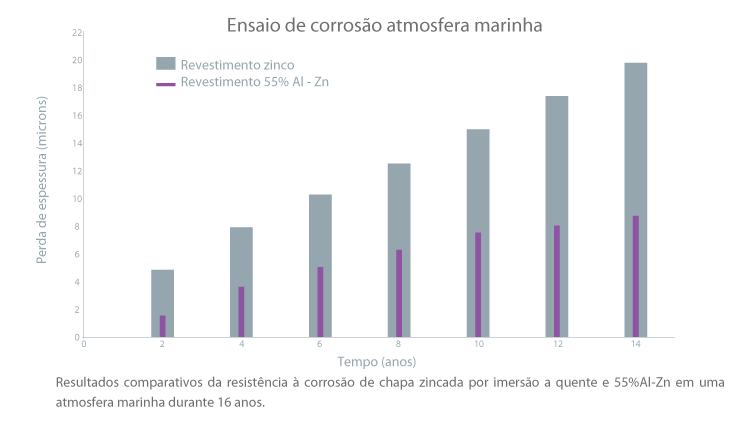

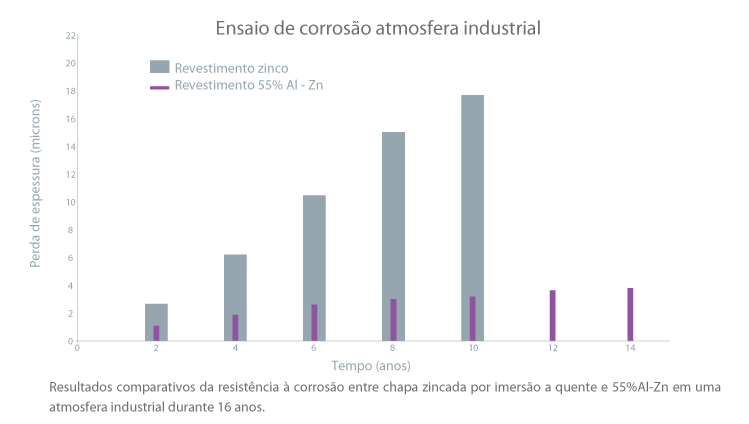

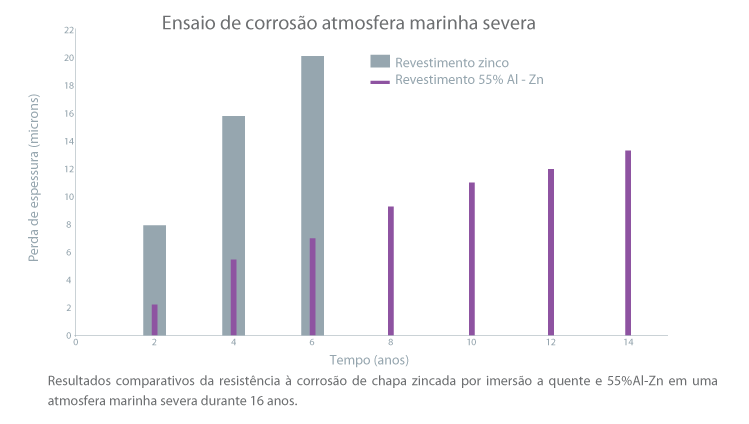

Galvalume ® is a steel sheet coated with 55%Al43,5%Zn1,5%Si alloy and combines aluminum durability with galvanic zinc protection, providing excellent resistance to corrosion in marine and industrial environments compared to existing zinc coatings on the market, resistance to oxidation at high temperatures and superior thermal reflectivity associated with a pleasant and distinctive look compared to other similar coatings. Its characteristics of formability, weldability and painting ease, associated with its mechanical properties, make it appropriate for applications in several segments.

Coating

Product Description

Typical Crystallization

Galvalume® coating obtained by standard solidification of the deposited layer, resulting in a surface with crystals visible to the naked eye.

This type of coating is recommended for general use, particularly for applications in the construction industry, major appliances and auto parts.

Coating Standards

| Technical Standard |

Coating |

Mass individual test (g/m²) |

Mass triple test (g/m²) |

| ASTM A792 |

AZM150 |

130 |

150 |

| AZM165 |

150 |

165 |

| AZM180 |

155 |

180 |

| AZ50 |

131 |

153 |

| AZ55 |

153 |

168 |

| AZ60 |

159 |

183 |

| NBR 15578 |

AZ150 |

130 |

150 |

| AZ165 |

140 |

165 |

| AZ180 |

155 |

180 |

Structural

Product Description

Structural steels are generally carbon manganese steel whose mechanical strength is obtained by a solid solution associated with thermo-mechanical processing conditions. These types of steel have high mechanical strength and are particularly suitable for sheet uses and applications that require simple folds and corrugations such as structural steel, storage silos and structures in general.

Available Dimensions and Examples of Standarts

Thickn. Min.

mm |

Thickn.Max.

mm |

Lgth.Min.

mm |

Lgth.Max

mm |

| 0,3 |

1,55 |

700 |

1300 |

Thickn. Min

mín |

Thickn. Max

máx |

Lgth.Min

mín |

Lgth.Max

máx |

| (0,0118) |

(0,061) |

(27,56) |

(51,18) |

| Technical Norm |

Degree |

Mechanical Property |

YL Min

[MPa] / KSI |

TS Min

[MPa] / KSI |

Elongation |

| Thickness |

Base |

Value % |

| ASTM A792 |

SS33/AZR230 |

[230] / 33 |

[310] / 45 |

Any |

50 |

20 |

| SS50/AZR340 (CL1) |

[340] / 50 |

[450] / 65 |

Any |

50 |

12 |

| SS50/AZR340 (CL2) |

[340] / 50 |

– / – |

Any |

50 |

12 |

| SS50/AZR340 (CL4) |

[340] / 50 |

[410] / 60 |

Any |

50 |

12 |

| SS80/AZR550 (CL1 e CL2) |

[550] / 80 |

[570] / 82 |

Any |

50 |

– |

| SS80/AZR550 (CL1 e CL2 |

[550] / 80 |

[570] / 82 |

Any |

50 |

3 |

| NBR 15578 |

AZR230 |

[230] / 33 |

[310] / 45 |

Any |

50 |

22 |

| AZR345 |

[345] / 50 |

[430] / 62 |

Any |

50 |

12 |

| AZR550 |

[550] / 80 |

[570] / 82 |

Any |

50 |

– |

Stamping

Product Description

The steels with a requirement for stamping are steels of low carbon alloy concepts (average printing), ultra low carbon IF – Interstitial Free (deep to extra deep stamping) for applications requiring more critical conformational levels for the manufacture of the parts, intended for more complex stamping processes. Steels of this class are used in major appliances, like refrigerators, washing machines and microwaves. In the automotive industry, they are commonly used for radiators

Available Dimensions and Examples of Standarts

Thickn. Min

mm |

Thickn.Max.

mm |

Lgth.Min

mm |

Lgth.Max

mm |

| 0,6 |

1,55 |

83 |

1350 |

Thickn. Min

(pol) |

Thickn. Max

(pol) |

Lgth. Min

(pol) |

Lgth. Max

(pol) |

| (0,0118) |

(0,061) |

(27,56) |

(51,18) |

| Technical Norm |

Degree |

Mechanical Property |

YS Mín

[MPa] / KSI |

Elongation |

| Thickness |

Base |

Value %

(min) |

r |

n |

| ASTM A792 |

FS |

[170/275] 25/40 |

Any |

50 |

24 |

1.0/1.4 |

0.16/0.20 |

| DS |

[140/240] 35/60 |

Any |

50 |

30 |

1.3/1.7 |

0.18/0.22 |

Commercial Quality

Product Description

Steels classified as commercial quality are simple alloy steels for applications which require less critical levels of conformation for the manufacture of the parts, recommended for bending, profiling and light stamping processes. Commercial quality steels are used in major appliances, like washing machines, refrigerators, stoves and microwaves, in applications such as cabinets, corners, doors and reinforcements in general and are also used in construction in structural profiles, roofing and side covers.

Available Dimensions and Examples of Standarts

Thickn. Min

mm |

Thickn. Max

mm |

Lgth. Min

mm |

Lgth. Max

mm |

| 0,3 |

1,55 |

700 |

1300 |

Thickn. Min

(pol) |

Thickn. Max

(pol) |

Lgth. Max

(mm) |

Lgth. Max

(mm) |

| (0,0118) |

(0,061) |

(27,56) |

(51,18) |

| Technical Norm |

Degree |

Mechanical Property |

YS Mín

[MPa] / KSI |

Elongation |

| Thickness |

Base |

Value (min)

% |

| ASTM A792 |

CS Type A |

[205/410] 30/60 |

Any |

50 |

20 |

| CS Type B |

[245/410] 35/60 |

Any |

50 |

20 |

| CS Type C |

[205/450] 30/65 |

Any |

50 |

15 |

| NBR 15578 |

AZC |

– |

– |

– |

– |

Last update on

June 2, 2021.

Back

Top

Contraste

Contraste